How To Make Your Own Low Cost Biodiesel Processor

Make sure to like Living Green and Frugally on Facebook, Shop at Amazon to help support my site and explore our PINTEREST BOARDS for innovative ways you can become self-sufficient.

How To Make Your Own Low-Cost Biodiesel Processor

If you’ve ever considered making your own fuel, building a low-cost biodiesel processor is a great place to start. Biodiesel is an eco-friendly alternative to traditional diesel, made from renewable resources like vegetable oils and animal fats. Not only is it better for the environment, but producing your own biodiesel can also save you money. Here’s an overview of how you can build a simple biodiesel processor at home, but for detailed instructions, make sure to check out this comprehensive guide.

What is Biodiesel?

Biodiesel is a renewable energy source made by converting oils or fats into fatty acid methyl esters (FAME) and glycerin through a process called transesterification. This fuel can be used in any diesel engine, often with little to no modification, making it an attractive alternative to fossil fuels.

Why Build Your Own Biodiesel Processor?

- Cost Savings: By making your own biodiesel, you can reduce your fuel costs significantly, especially if you use recycled cooking oil.

- Environmental Impact: Biodiesel is biodegradable, non-toxic, and burns cleaner than traditional diesel, reducing greenhouse gas emissions.

- Self-Sufficiency: Creating your own fuel gives you independence from oil companies and contributes to a sustainable lifestyle.

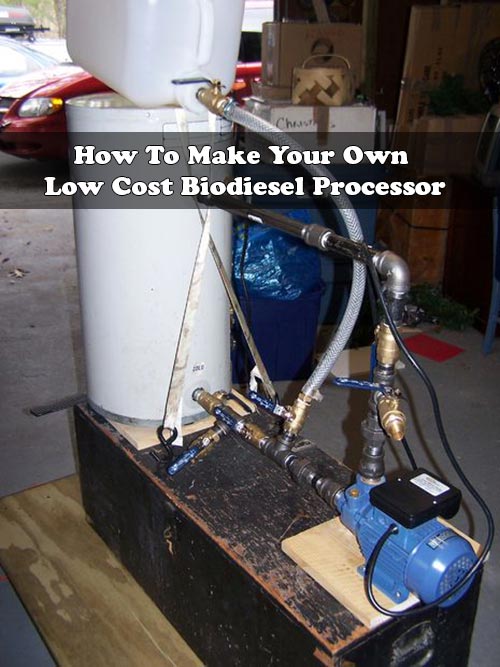

To build your own processor, you’ll need a few basic materials like a used water heater, a chemical-resistant pump, piping, and a few other components. The process involves converting used vegetable oil or animal fat into biodiesel by heating and mixing it with a catalyst.

For a step-by-step guide on how to construct the processor, including detailed diagrams and tips, visit this link.

View this post on Instagram

How Does a Biodiesel Processor Work?

A biodiesel processor is essentially a system that mixes and heats oils to convert them into biodiesel. The process generally involves:

- Filtering and Heating the Oil: The used cooking oil is filtered to remove debris, then heated to around 55°C (131°F) to prepare it for the chemical reaction.

- Mixing with a Catalyst: The heated oil is mixed with a catalyst made from methanol and a base (like sodium hydroxide). This mixture is circulated within the processor to ensure thorough mixing.

- Settling and Separating: After mixing, the solution is allowed to settle. Biodiesel will separate from the glycerin, which can then be drained off.

- Washing and Drying: The biodiesel is washed to remove impurities and then dried before use.

Building this processor might seem daunting, but with the right guidance, it’s entirely achievable. To dive into the full construction process and see how others have successfully built their own processors, check out this detailed tutorial.

Get Started Today!

Making your own biodiesel processor is a rewarding project that offers significant financial and environmental benefits. Whether you’re a DIY enthusiast or someone looking to reduce your carbon footprint, this is a great way to take control of your energy needs.

For all the detailed steps, materials, and expert advice, make sure to visit this comprehensive guide. It will walk you through everything you need to know to start producing your own biodiesel at home.